The Metal Sheet Automatic Ironworker Shearing and Punching Machine is a versatile and efficient machine that is designed for cutting and punching metal sheets. The machine uses advanced technology to provide precise cuts and punches, making it an ideal solution for businesses that work with metal sheets on a regular basis.

One of the key features of the Metal Sheet Automatic Ironworker Shearing and Punching Machine is its ability to shear and punch metal sheets with high precision. The machine uses advanced hydraulic technology to provide accurate and consistent cuts and punches, ensuring that each piece of metal is cut and punched to the correct size and shape.

Another key feature of the machine is its versatility. The Metal Sheet Automatic Ironworker Shearing and Punching Machine can be used to cut and punch a variety of different metals, including steel, aluminum, and copper. This makes it an ideal solution for businesses that work with different types of metal sheets.

The machine is also highly efficient. It is capable of cutting and punching multiple sheets of metal at the same time, which means that it can handle high-volume production runs. This makes it an ideal solution for businesses that need to produce large quantities of metal sheets quickly and efficiently.

In addition to its efficiency, the machine is also highly durable and reliable. It is designed to be rugged and long-lasting, which means that it can be used for years without needing to be replaced. This makes it an ideal investment for businesses that are looking for a long-term solution for their metal cutting and punching needs.

In conclusion, the Metal Sheet Automatic Ironworker Shearing and Punching Machine is a versatile and efficient machine that is ideal for businesses that work with metal sheets on a regular basis. It is capable of providing precise cuts and punches, and is versatile, efficient, and reliable, making it an ideal investment for businesses that are looking for a long-term solution for their metal cutting and punching needs.

Quick Description

- CNC or Not: CNC, Normal

- Condition: New

- Nominal Force (kN): 90

- Power Source: Hydraulic, Hydraulic

- Place of Origin: Anhui, China

- Year: 2021

- Voltage: 220/380/400/415V, 380V/220V/230V/415V/ Optional

- Dimension(L*W*H): 1950*900*1950mm

- Weight (T): 2.6

- Key Selling Points: Multifunctional

- Warranty: 2 years

- Showroom Location: Egypt, United Kingdom, Viet Nam, India, Mexico, Thailand, Sri Lanka, Malaysia

- Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

- Machine Type: hydraulic ironworker machine

- Max. Cutting Thickness of Steel Plate: 20mm

- Weight: 2.6T

- Keyword: ironworker machine

- Shearing Angle: 8

- Motor Power (kW): 7.5

- System: Normal

More Details

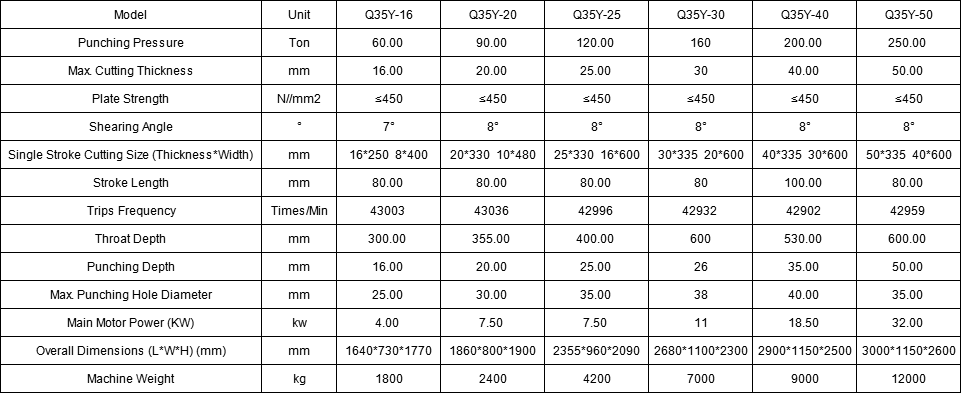

Q35Y 50 40 160T hydraulic ironworker machinery cutting machine for punching

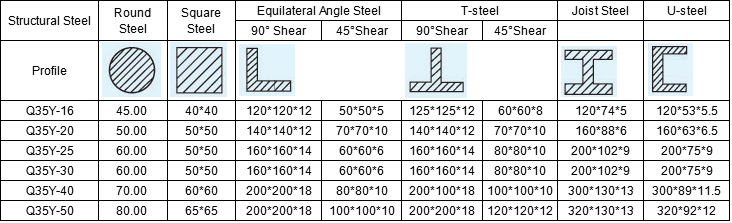

Multi-function Hydraulic Iron worker ironworker is the latest product of the punching and shearing machine which can cut , punch , notch and bend all kinds of materials such as plate , flat bar , square bar , round bar , equal , angle, channel ,I-beam and so on .

Standard Components

1. Seal rings Japan NOK

2. 2 independent hydraulic cylinders Anhui Wuyang

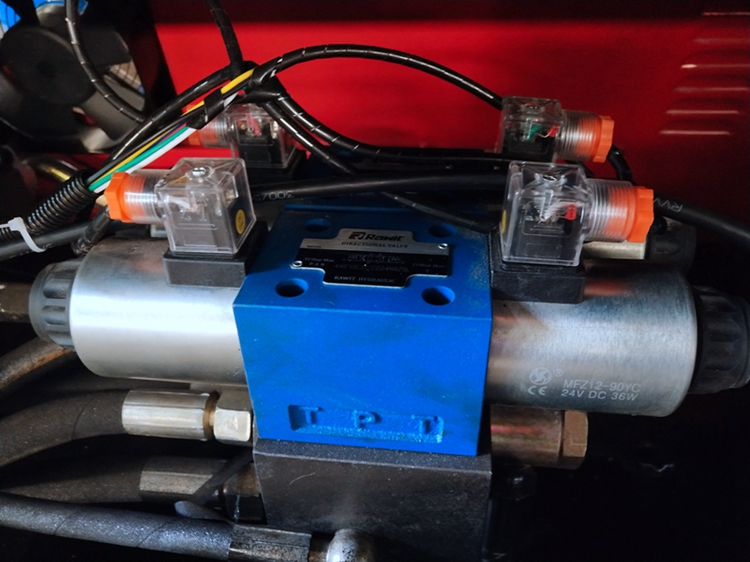

3. Hydraulic system German Bosch Rexroth

4. Gear pump Shanghai Hangfa

5. Motor Siemens

6. Electric components Schneider

7. Large punch table with scales

8. 2 shielded foot controls

9. Manual back gauge

10. 5 working stations for punching shearing notching bending

Optional Components

1. Punching machine: Movable work light

2. Overload protection on hydraulic system

3. Electric back gauge

4. Optional bending attachment

5. Adjustable stroke controls with indicators on both cylinders

Detailed Images

ironworker punching machines parts

Name: shape shearing parts

Round and square bar shear has multiple holes for a variety of sizes. Adjustment hold down device for round/square bar,channel/beam cutting. Large strong guarding or max safety.

The angle shear has the ability to cut angle at 45 degree both top and bottom leg. This give the operator to make a picture frame corner for perfect welds.Diamond shaped blade for quality cuts that is minimal material lost and deformity.

hydraulic ironworker hole punch and shear machine

Name: Notching parts

Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and 3 gauging stops for precise positioning.

Notching is a metal-cutting process used on sheet metal or thin bar stock, sometimes on angle sections or tube.

sheet metal hydraulic ironworker

Name: Punching parts

Full range of universal punches and dies are available. Unique style allows for large angle iron punching and large channel punching.

Large viewing window on stripper swing away design for ease of operation. Large 2 piece gauging table with rulers and stop as standard fittings. Quick change coupling nut and sleeve for rapid replacement of change.

double cylinder ironworker machine control parts

Very easy to operate, hand operating, safe and easy